Bread Staling - Concept, Process And Factors Influencing It

The Concept of ‘Bread Staling’

The Concept of ‘Bread Staling’

Bread ‘Staling’ in a broad context refers to all the changes, which occur in bread after baking causing it to become ‘stale’ resulting in decreased consumer acceptance and spoilage. Bread staling is predominantly a process of chemical and physical change in the baked bread which reduces it palatability by impacting its taste and also makes it dry and leathery in texture. The term does not cover the changes that result from the action of spoilage organisms. For a bakery, this is a matter of concern as it significantly affects the value of the saleable product resulting in the impact on profitability and its reputation.

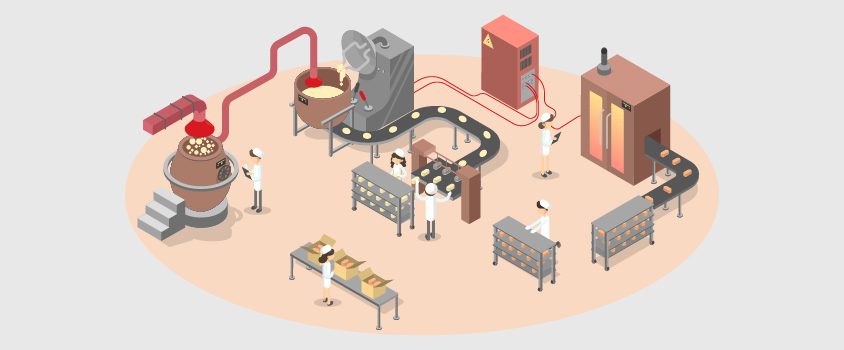

The Process of Cooling of Bread

As soon as a bread is removed from the oven after being baked, it undergoes various changes that impact its taste.

The changes happen in the process of cooling. As the bread undergoes rapid cooling, alcohol vapours, carbon dioxide and water vapour diffuse through the crust of the bread and is replaced by ambient air. Escaping water vapour condenses on the cold surfaces that are in contact with crust in a phenomenon that is known as ‘sweating’ of bread. This term is used to describe the cooling period of the bread after baking. During this time, there is a high percentage of water content in the crumb which can easily cause the bread to form balls or pellets even with the slightest pressure applied.

About two third through the cooling stage, the crust is crisp and pleasantly scented by the escaping making it very appetizing. However, the odour of the crumb is less engaging at this stage. Furthermore, if chewed, the bread tends to form the lump of mass in the mouth reducing the ability of our body to digest it easily.

Towards the end of its cooling phase is when the bread reaches its optimum. Here an equilibrium is being reached between the diffusion of aromas from the crust toward the crumb and vice versa. The crust has a brilliant shine and still possess a fine aroma, and it has a most agreeable texture and taste when eaten.

Factors that influence bread staling

Physical and chemical changes continue to happen within the bread well past the cooling phase. The bread continues to lose moisture and get dry. However, drying of bread should not be confused with staling although drying is one of the factors which accelerate reactions leading to bread staling.

The most important factor that influences bread staling is the starching effect. Starching effect is when the starch undergoes gelatinization or swelling when heated in the presence of water. In this state, starch links with and is deposited onto coagulated gluten to form the crumb structure. This is an amorphous and unstable stage.

As time passes, the starch gradually changes into its original crystalline form. This change is evident in the progressive hardening of the crumb and the corresponding loss of its softness and elasticity also reducing its flavour.

On the other hand, after coagulation, the gluten begins to form a gel, which in turn begins to evolve irreversibly to a harder stage. However, if the gluten percentage is high, it slows down the effect of staling.

These evolutionary changes that occur during staling of bread influence many other factors like changes to dough constituents or modification in production technology.

Slowing Down Staling in Bread

Staling cannot be avoided as it is a natural process of ageing in bread however it can be slowed down by altering certain physical and chemical components in bread. Flour is the major ingredient in bread and given below are some attributes of flour which can slow down the process of staling:

- An above average protein/Gluten level.

- A damaged starch level that is slightly higher than average, enabling better water absorption and helping the amylases to achieve a higher maltose production.

- A slightly higher than average amylase content.

Steps/considerations to improve the keeping qualities

Following are some of the steps/ considerations, which can improve the keeping qualities during the dough and bread production:

- A good hydration of the flour

- Appropriate dough mixing, which ensures the formation of a good gluten network while avoiding any excessive oxidation

- Use of an additive that contains a small amount of lecithin (when needed)

- A sufficient first fermentation, or the addition of a fermented culture during mixing, which helps to develop an appropriate acidity level in the dough

- Techniques of loaf moulding that avoid excessive or rough degassing of the dough

- Final fermentation and baking of the formed raw dough pieces that will be adequate to produce loaves with a reasonable specific gravity (not excessive)

- Baking at an appropriate temperature, which will ensure that the loaves undergo a balanced baking (i.e. neither too hot, cool, dry, nor humid)

Additives used and their dosages

The bakers can also acidify the dough to slow down bread staling and avoid bread spoilage. One of the below acids can be used to acidify to the dough. (The usage level is as per the maximum permitted in France for 100 kg flour).

+ Pure lactic acid (300 g)

+ Calcium phosphate (700 g)

+ Pure acetic acid (200 g)

+ Food grade vinegar (2 L)

+ Calcium acetate – free of copper and zinc (430 g).

We hope the information in this blog has been valuable to you. Do share your comments, queries or concerns regarding this blog with us.

Have a topic in mind you want us to write on? We are open to hearing from you. Kindly write to us on support@swissbake.ch.

Thank You for reading.